MATERIALS

BIOMANUFACTURED ALGAE OIL

- High levels of monounsaturated fat; low in saturates and polyunsaturates

- Highly stable

- 100% biobased content and readily biodegradable

- Low odor

- Highly enriched for triolein

- Industrial

- Plasticizer

- Ingredient in lubricants

- Leather processing (fatliquoring)

- PU system flush

- Food & Feed

Polyurethane Cast Elastomers

- Thermoset

- Algae-derived

- Hardness, flexural strength and impact resistance can be tuned to meet needs of the end-use application

- Shore A and D formulations available

- Can be pigmented in an array of colors

- No added mercury, tin, MOCA, or TDI

- Can enable the manufacture of products containing USDA Certified Biobased content up to 66% (ASTM D6866)

- Explore samples of Checkerspot® Cast PU

- Ski sidewall made with AlgalCast has 15% greater flexural strength than traditional petroleum-based ABS sidewalls at room temperature, and 60% greater flexural strength at low temperatures*

- 138% better damping than a traditional petroleum-based ABS sidewall

- Manufacturing AlgalCast can reduce plastic waste compared to use of extruded plastic sidewalls

- Sidewall cast, unlike extruded plastic, forms an intimate bond to wood core eliminating the need for glue/resin

- Utilizing the cast urethane can reduce raw material input because AlgalCast can be dispensed to desired thickness and depth depending on end-use application

* Example of one formulation used in prior year ski models

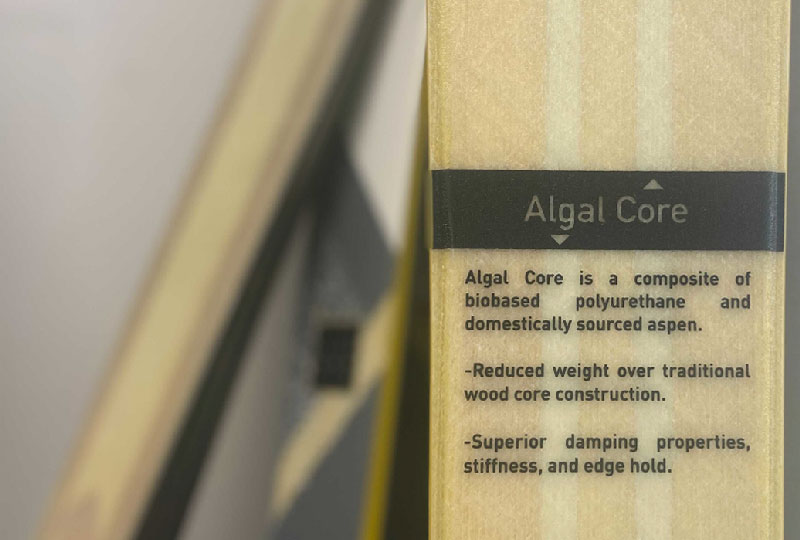

Rigid Polyurethane Foams

- Rigid, high-density algae-based polyurethane foam with a closed cell structure

- Utilizes water as a blowing agent (no cyclopentane, n-pentane, methyl formate or hydrofluorocarbons)

- No added mercury, tin, MOCA, or TDI

- Can enable the manufacture of products containing USDA Certified Biobased content up to 41% (ASTM D6866)

- Lightweight composite made from Checkerspot® AlgalFoam and wood (e.g., aspen), utilized in ski and snowboard cores

- Can be manufactured with a variety of wood species

- Can be fine-tuned for lightweighting and damping

- Enhanced compressive strength to withstand common layup techniques

TeXTILE FINISHES

Commercialized by Beyond Surface Technologies

- 100% biocarbon content

- Improves wicking and moisture management

- Reduces drying time - fast dry

- Readily biodegradable

- Up to 80% lower carbon footprint vs. petroleum-based wicking finishes

*Data provided by Beyond Surface Technology, our partner and the makers of miDori® bioWick

- PANGAIA's Activewear line pulls moisture away from the skin and towards the surface of the fabric for evaporation

- Helps to keep the body cool and dry when working out

- Excellent durability

*Data provided by PANGAIA

RECYCLED MATERIALS

- Recycled composite of fiberglass, wood, AlgalCast, and biobased resin derived from reclaimed production waste

- Can be molded or routed into a variety of shapes for a diverse range of applications

- Provides an opportunity to integrate recycled content into product construction, diverting waste from landfill

- For skis, provides ~35% better binding screw retention strength than the previously used maple inserts

- For snowboards, 5mm Spiral Plate insert packs enable ~5% better binding retention strength than inserts surrounded by traditional aspen wood.

- Spiral Plate insert packs for snowboards provide a wider platform for power transfer, resulting in better energy transmission to the snowboard’s core

Better Products Bring Biology Inside

An incredible number of the products we interact with on a day-to-day basis rely on petroleum and other unsustainable sources of oil. With a single microorganism, we're aiming to change that. When you choose Checkerspot® materials, the butterfly mark serves as a signal that the product contains a better source of oil. The butterfly shows which products bring Biology Inside, prioritizing both their performance and sustainability — since we believe that having to choose between the two is a false choice.

EcoVadis Silver

We're committed to continuous evaluation of our policies, supply chain, and actions related to social and environmental impact and sustainable procurement. We're proud to have earned a Silver rating from EcoVadis, one of the leading international monitoring agencies for sustainability in global supply chains. Their team of sustainability experts analyzed and cross-checked our data to rate our performance at the Silver medal level and we continue to strive for improvement year over year.

Learn More

It takes a community united behind a shared vision to create long-lasting, sustainable change.

Are you interested in partnering with us or curious about our materials?

We want to hear from you.